No visible distortion

- No lensing

- No distortion like wavy glass afterwards

Effective 3 step system

- Coded RevoDisks

- Fast result

- Special design

Deep damage

- Scratches

- Grinding and welding spatter

- Vandalism damage

- Etched-graffiti

- Acid tags

Professional solution

- Glass production facilities

- Glassrepair professionals

- Public transport industry

- Cleaning companies

- Vandalism recovery specialists

Applications of glass renovation and glass protection

Almost everywhere where glass is used, it is exposed to damage and contamination. The RevoGlas systems and accessories are suitable for processing almost all types of glass and can be used under almost all circumstances. These problems can be solved relatively easily with the RevoGlas glass renovation system. The technique is used in many areas such as: construction sector, yacht and shipbuilding, automotive and transport, wellness and in the glass production sector.

Construction

Yachting

Automotive

Wellness

Transport

3 STEP SYSTEM

GRINDING

PRE-POLISH

POLISHING

View our systems

-

RevoGlas Starter Kit

€249,00 excl VATSmall and compact kit to remove scratches, acid-graffiti or lime from glass

-

RevoGlas Starter XL Kit

€429,00 excl VATRevoGlas Starter XL Kit with various Revodisks (5 “& 6”), backing discs, Revofelt polishing pad and supplies

-

RevoGlas LITE system

€1.599,00 excl VATProfessional ready-for-use Glass Renovation system to remove scratches from glass, including polisher, 5″ and 6″ Revodisks and skilful black case

-

RevoGlas Pro system

€2.499,00 excl VATThe RevoGlas Pro System is a fully professional ready-to-use glassrenovation package including polisher for work both stationary and on location

STARTER |

START XL |

LITE SYSTEM |

PRO SYSTEM |

|

| Scratch removal |

||||

| Acid-graffiti removal |

||||

| No distortion |

||||

| Applicable on all types of glass |

||||

| Training and certification possible |

||||

| 3″ RevoDisks |

||||

| 5″ RevoDisks |

||||

| 6″ RevoDisks |

||||

| 8″ RevoDisks |

||||

| Technical support |

||||

| C# and D# RevoDisks for deep damage |

||||

| System storage case |

||||

| High grade fieldcase |

||||

| Makita professional polishingmachine |

||||

| Special backings pads |

||||

| Number of included RevoDisks |

20 | 40 | 50 | 100 |

| RevoFelt polishingpads |

||||

| Finishing Spray |

||||

| Polishing compound |

||||

| Spray bottles |

||||

| IR temperature gun |

||||

| Wire brush |

||||

| Dust mask |

||||

| Rasp file |

||||

| Performance guarantee |

||||

| Extensive user manual |

||||

| Personal instruction |

||||

Price excluded vat |

€ 249,00 |

€ 429,00 |

€ 1.599,00 |

€ 2.499,00 |

ORDER NOW |

ORDER NOW |

ORDER NOW |

ORDER NOW |

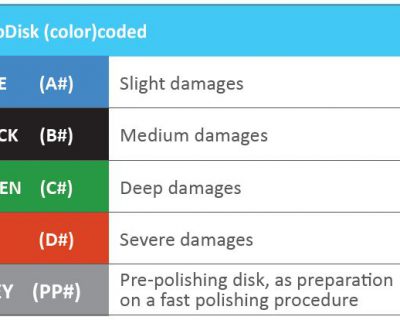

Revodisks

The unique RevoDisks are the base for a good result in glass renovation and are available in four different sizes (3” 5” 6” 8”) and five grinding ranges to match every type of scratch or damage. It is not necessary to go through to all individual steps, so time is saved. The revolutionary design and the construction are proprietary to the RevoGlas RevoDisks. The RevoDisks are build with a base-material that keeps sharp for long time. The RevoDisks also employ a special cushioned design that prevents leaving trace marks, swirls, lenses or distortion even on deep damages. The disks are coded for quick identification and easy of use.

Polishing Compound

RevoGlas Polishing Compound is an advanced formula, soft setting mixture to assist in the scratch removal and glass

renewal process. After application of the PP# pre-polishing RevoDisk (step 2 in the proces), the polishing phase is the finishing of the glass repair.

Finishing spray

The finishing spray easliy removes the last bits of the polishing compound and cleans the glass completely after the repair.

Pictures of glass renovation before and after

Most damage to glass can be repaired. The before and after photos below give a good idea of what is possible with the RevoGlas Glass Renovation Systems.

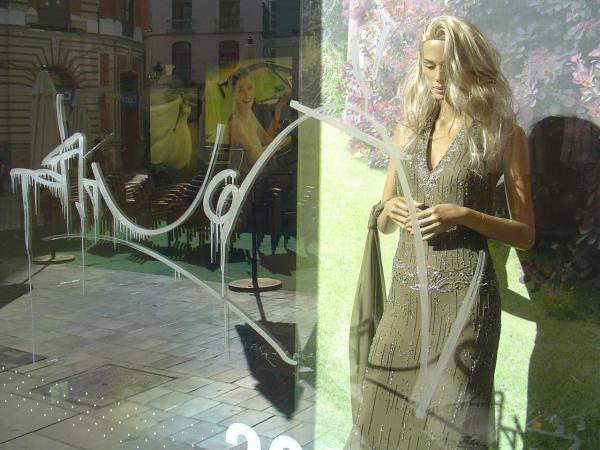

Acid tags on shopping window in Amsterdam

Fully restored without distortion with RevoGlas System

Scratches in a door of glass

Scratches completely removed from the door of glass with the RevoGlas system

Glass facade contaminated with cement residue

Glass facade cleaned with RevoGlas system

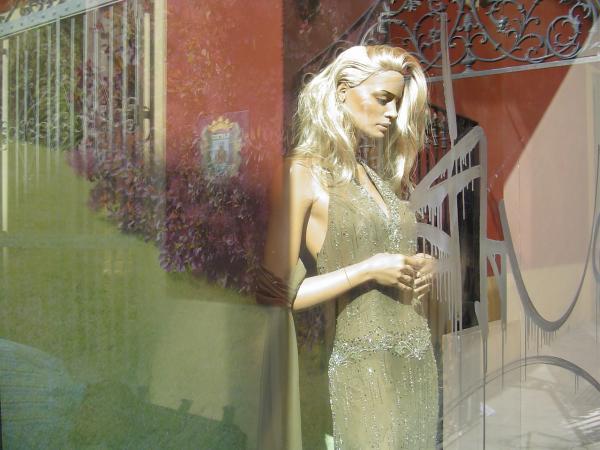

Acid tags on shopping window in Malaga

Fully restored without distortion with the RevoGlas System

Scratches in shopping window

Scratches completely removed with the RevoGlas System

Acid tags on a car window

Result in-between/ partially removed

DO YOU WANT MORE INFORMATION?

PLEASE CONTACT US.

MORE INFORMATION & DOWNLOADS

Why remove scratch from glass instead of replacing it? The global demand for flat glass is approximately 45 million tons per year, of which 50% is supplied by Asia, 27% by Europe and 15% by North America. Of this total, 70% is used for construction, 20% for interior design and decoration, and 10% for the automotive and transport industry.

As company, we see it as our social duty to apply sophisticated techniques so the production of flat glass can be reduced. Removing scratches instead of replacing the glass saves the environment by reducing the use of raw materials and the amount of glass waste to be landfilled. The production process of glass from sand and soda consumes a lot of energy and is accompanied by the emission of flue gases such as CO2. By limiting this to some extent, we also contribute to saving the environment and offer a green alternative to replacement.

The CO2 emissions during the production of glass are (according to VROM Protocol 9064 2009): - 0.18 kg CO2 per kg glass (0.45 kg CO2 per m2 per mm thickness) Including transport of raw materials and end product: 0.5 kg CO2 per kg of glass (1.25 kg CO2 per m2 per mm thickness) (The weight of glass is 2.5 kg/m2 per mm thickness) For comparison, the average CO2 emission of a passenger car is 0.13 kg per km driven.

Instructions for use and MSDS go to the webshop.

References